Keven Talks Sails: Crosscut VS Triradial Sail Cutting

Nov 25, 2021

Over the last decade, sailcloth weaving equipment has evolved and allowed the production of low crimp warp oriented woven cloth of medium to heavy weights. We have had light weight warp wovens of 200g/m2 (4oz) or lighter for much longer than that, but the finer denier weaves of light sailcloth allowed that with older looms and setups. Why is this important? This new loom technology is very important because it allows sailmakers to make better warp cut woven sails for boats 25-50’ long.

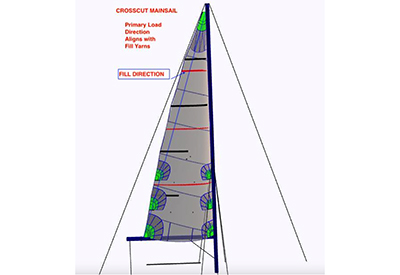

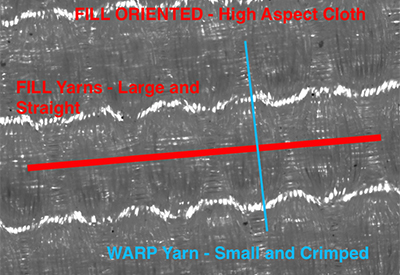

Let’s start by clarifying what a crosscut sail is. The crosscut panel layout aligns the fill (short) edge of the sailcloth roll with the leech edge of the sail. Most of the sail load goes from clew to head up the leech. Secondary sail loads go from corner to corner along the foot and luff edge. Tertiary loads support the body of the sail and radiate to the corners. The crosscut sail addresses the Primary and Secondary Loads well and relies on the bias stability of the cloth to support the Tertiary loads. It works very well to prevent leech stretch, but the sail does require a firm and somewhat stiff finish to keep the bias loads under control a close up of some Fill or High Aspect cloth used for Crosscut Sails

a close up of some Fill or High Aspect cloth used for Crosscut Sails

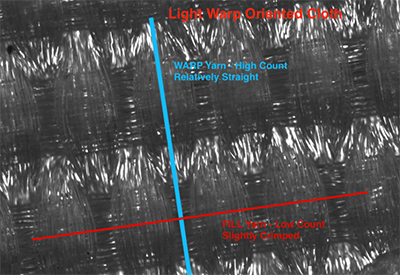

Below, take a look at the Medium to Heavy Weight Warp Oriented cloth for Radial sails and you can see the warp tunnels that are straight and raised to the surface.

{youtube}bcfpvySDO3U{/youtube} Light Weight Warp Cloth uses a different strategy and has a very high count of warp threads.

Light Weight Warp Cloth uses a different strategy and has a very high count of warp threads.

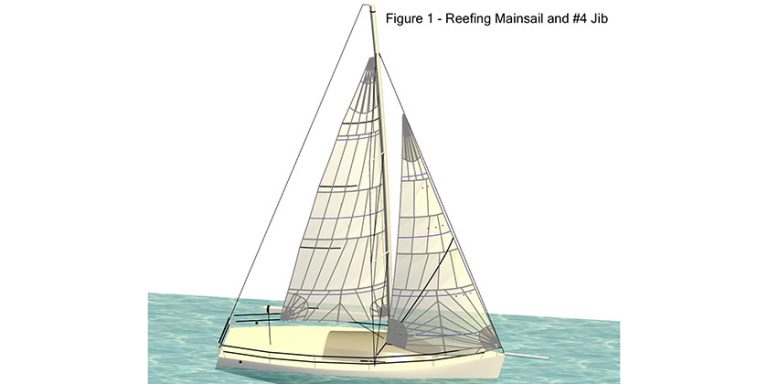

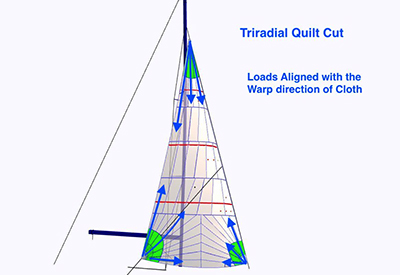

Let’s take a look how this Warp cloth is used in a Triradial Cut Sail.

The loads are now aligned with the primary, secondary and tertiary loads, and the cloth is efficiently distributing the strain over a very large area of the sail. This triradial panel layout is able to take about 30% more load than a similar weight cloth in a crosscut configuration. Another advantage is that you can use a lighter weight to get better setting in light wind.

Now you have a basic understanding of two major types of sail cuts. The crosscut sail is a stout performer if you are using a fill oriented cloth, and is very efficient in roll cloth usage and cost. The triradial layout does have a higher amount of cutting waste and has significantly more accurate seaming and sewing to perform. This leads to a higher cost product, but also gives better shape holding and performance over time.

Now you have a basic understanding of two major types of sail cuts. The crosscut sail is a stout performer if you are using a fill oriented cloth, and is very efficient in roll cloth usage and cost. The triradial layout does have a higher amount of cutting waste and has significantly more accurate seaming and sewing to perform. This leads to a higher cost product, but also gives better shape holding and performance over time.

Keven Piper, two-time Shark 24 World Champion, founded Hamilton, ON-based Bay Sails in 1998.

Keven Piper, two-time Shark 24 World Champion, founded Hamilton, ON-based Bay Sails in 1998.

email: baysails@gmail.com